TTV was founded in 1982 and since then we have been growing continuously mainly thanks to our staff, which is one of the cornerstones of our company and to the continuous technical innovations of our products.

TTV valves are technologically advanced and highly competitive thus they are currently very succesful in many countries all over the world.

TTV work is focused on design, production and quality. Sales all over the world are managed through an authorised distributor network.

TTV has foundries in Europe and Asia, which are always homologated, and constantly invests to produce with more quality and effectively.

Assembly and testing are always carried out in our facilities.

TTV can give very short delivery times as it has got a large stock of valves and spare parts in our facilities.

The quality of our valves is fully guaranteed as 100% of them are hydrostatically and bidirectionally tested before shipping.

Our valves have the following additional advantages achieved during over 30 years´ of research and development:

• Reduced dimensions and weights.

• Easy assembly, disassembly and maneuvering.

• Simple manual regulation and electrical, pneumatic and hydraulic automation.

• Auto cleaning and maintenance free.

• Fully tightness and minimum leakage.

• Full guarantee and after sales service.

Market sectors

TTV valves are mainly used in:

• Shipbuilding and offshore

• Water treatment and supply

• Irrigation systems

• Building

• Power generation

• Food industry

• Paper mills

• Chemical and petrochemical industry

• Mining

• Steel industry

• Sugar mills

• Cement industry

• Pharmaceutical industry

Global service

TTV provides to our clients a global service, from technical support to select suitable valve to customized design and manufacturing to achieve special services.

For more info visit: http://en.ttv.es/

BUTTERFLY VALVES SOFT SEATED

- Valves certified and approved for different applications

- Concentric and eccentric design

- Wafer, lug, flanged, double flanged and grooved type

- Pressure rating: PN6, PN10, PN16, PN25, PN40, class 125 lbs, class 150 lbs

- Temperature rating: -40 ºC - 160 ºC

- Diameters: DN32mm (1 ¼”)- 3000mm (120”)

- Available in any international standard (API, BS, DIN, ISO, AWWA, etc)

- 100% tight shut off, 0% leakage

- Replaceable or vulcanized seat (elastic ring selection can be done by our technical department according to valve work conditions)

- Possibility of operation through different manual controls (hand lever, racket lever, gearbox,…), electric actuator, pneumatic actuator, hidraulic actuator, …

- One piece and dry shaft. The fluid is not in contact with either the shaft or the body

- Bi-directional sealing

- Lightweight design for easier installation

- Self-cleaning

- Easy maintenance

- Low operating torque

- Aerodynamic butterfly design minimizes pressure drop

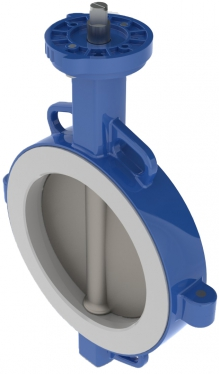

BUTTERFLY VALVES HIGH PERFORMANCE PTFE SEATED

- Valves certified and approved for different applications

- Concentric and eccentric design

- Wafer, lug, flanged, double flanged and grooved type

- Pressure rating: PN6, PN10, PN16, PN25, class 125 lbs, class 150 lbs

- Temperature rating: -25 ºC - 200 ºC

- Diameters: DN32mm (1 ¼”) - 600mm (24”)

- Available in any international standard (API, BS, DIN, ISO, AWWA, etc)

- 100% tight shut off, 0% leakage

- High resistance to the action of chemical agents and solvents

- Low operating torque

- Possibility of operation through different manual controls (hand lever, racket lever, gearbox,…), electric actuator, pneumatic actuator, hidraulic actuator, …

BUTTERFLY VALVES COLOSSUS: HIGH PERFORMANCE METAL SEATED

- Valves certified and approved for different applications

- Concentric, double-eccentric and triple eccentric design

- Wafer, lug and flanged type

- Eccentric pressure rating: PN6, PN10, PN16, PN25, PN40, PN50, PN64, PN100, class 125 lbs, class 150 lbs

- Temperature rating: -196 ºC - 760 ºC

- Diameters:

- Concentric design: DN50mm (2”) – 1600mm (64”)

- Eccentric design: DN50mm (2”) – 600mm (24”)

- Available in any international standard (API, BS, DIN, ISO, AWWA, etc)

- Eccentric design: 100% tight shut off, 0% leakage

- Fire safe

- Suitable for cryogenic use

- Possibility of operation through different manual controls (hand lever, racket lever, gearbox,…), electric actuator, pneumatic actuator, hidraulic actuator, …

GLOBE VALVES

Stem

The stems of JC globe valves are forged from one piece and ACME threaded, then mechanized and finally provided with a smooth finishing in order to minimize friction.

Body and Bonnet Gasket

The design of the body-bonnet gasket varies depending on the class of the valve.

Class 150 to 600 globe valves consist of a circular male-female connection with a graphite or spiral wound gasket.

Class 900 and above globe valves consist of a ring type joint.

In pressure seal designs the sealing is achieved through a gasket that takes advantage of the internal pressure of the line. The material most commonly used is high-purity graphite being located between the body and the body retainer ring.

Body and Bonnet

Bodies and bonnets are high quality cast and afterwards precisely machined, directing the attention to prevent stress concentration.

Bonnets are made either of one piece only –the yoke then being an integral part of it – or have two pieces, depending on the size of the valve. This ensures the perfect alignment with the body what leads to an accurate opening and closing.

Bodies of globe valves are designed considering the same characteristics as gate valves, which in this case means that the disc is guided in bigger valve sizes or high pressure service in order to avoid vibrations and better seat.

Backseat

All JC gate and globe valves have backseat threaded in the bonnet, or for the pressure seal valves, welded to the bonnet.The hard facing is stellite 6 or equivalent.

GATE VALVES

Body and Bonnet

Bodies and bonnets are high quality cast and afterwards precisely machined, directing the attention to prevent stress concentration.

The bodies of gate valves consist of a straight through port that guarantees minimal turbulence and resistance to flow. In both designs, bolted bonnet and pressure seal, the bodies consist of guide slots to accommodate the wedge during opening or closing of the valve.

Bonnets are made either of one piece only –the yoke then being an integral part of it– or have two pieces, depending on the size of the valve. This ensures the perfect alignment with the body what leads to an accurate opening and closing.

Backseat

All JC gate and globe valves have backseat threaded in the bonnet, or for the pressure seal valves, welded to the bonnet. Into pressure seal the hard facing is stellite 6 or equivalent.

Stem

The stems of JC gate valves are forged from one piece and ACME threaded, then mechanized and finally provided with a smooth finishing in order to minimize friction.

In gate valves, the union of stem and wedge shall be in T form, designed to prevent the stem disengaging itself from the wedge while being in service. This design includes a conical raised surface that presses the seat against the bonnet backseat in the fully open position.

Body and Bonnet Gaskets

The design of the body-bonnet/gaskets varies depending on the class of the valve.

Class 150 gate valves consist of a square joint in 2” and an oval one for all other sizes. Depending on the valve service it can be supplied flat-face gasket with graphite or PTFE.

Class 300 and 600 valves consist of a circular spiral wound gasket.

Class 900 and above gate valves consist of a ring type joint.

In pressure seal designs the sealing is achieved through a gasket that takes advantage of the internal pressure of the line. The material most commonly used is high-purity graphite being located between the body and the body retainer ring.

Flexible Wedge

All JC gate valves 3” and above valves feature a flexible wedge unless otherwise specified by the customer. The flexible wedge shifts along the body of the valve during opening and closing, being held in position by a guide slot that minimizes the friction between body seat and wedge. This design is especially suited to compensate slight thermal deformations produced by the pipe or the valve itself safeguarding a better sealing between body and wedge seats.

CHECK VALVES

Body and Cover

Bodies and covers are high quality cast and afterwards precisely machined, directing the attention to prevent stress concentration.

The design characteristic of check valves is the unobstructed passageway, with a full-opening when required.

Body and Cover Gasket

The design of the body/cover gasket varies depending on the class of the valve.

Class 150 to 600 check valves consist of a male-female connection with a graphite or spiral wound gasket.

Class 900 and above check valves consist of a ring type joint.

In pressure seal designs the sealing is achieved through a gasket that takes advantage of the internal pressure of the line. The material most commonly used is high purity graphite being located between the body and the body retainer ring

BALL VALVES

- Full and Reduced bore.

- Floating and Trunnion mounted ball.

- Soft and Metal seats.

- Castings Quality as per ASME B16.34 Mandatory Appendix I to IV in ASME valves and Severity Levels S3-V3 to DIN 1690 and EN 10203 in EN-DIN valves.

- Polished ball Ra 1 in soft seated valves (in metal seated valves ball is lapped); grinded stem Ra 1.6.

- Full traceability of shell components, upon request, ball and stem as per EN 10204 3.1.

- Antistatic device integral with the stem.

- Viton A, Aflas or Kalrez primary stem seal an secondary graphite packing.

- NACE MR.01.75 wetted parts and bolting as Standard.

- Fire safe as standard construction ISO 10947 : 2004 and

- API 607 : 3rd, 4th, 5th edition.

- Fugitive emisions EN-ISO 15848-1.

- SIL 3 (Safety Integrity level 3).