Renold Gears designs and manufactures a complete range of gearing solutions including: worm gears, bevel and helical drives.

Whether you need a standard solution, available off the shelf, or a custom solution were our experienced Engineering Team will design a gearbox to meet the specific needs of your application, we have a solution for you.

We also have a dedicated Service Team who offer fast gearbox refurbishment of all makes and types of industrial gearboxes.

for more info visit www.renold.com

R Series

In-line helical gear unit with torque capacities up to 20,000Nm, power up to 160kW and ratios up to 58:1 in two stage and up to 16,200:1 in combined form.

Can be supplied as double, triple, quadruple and quintuple reduction units, foot or flange mounted. Available as motorised, motor ready or as a reducer with a keyed input shaft.

- Reduction gear and geared motor options

- Power up to 160kW covering the majority of drive requirements

- Ratios: up to 58:1 in two stage, up to 16,200:1 in combined form offers wide speed range

- Output torque up to 20,000Nm providing low cost per Nm

- Interchangeable Euro dimensions for ease of replacement

- Accepts standard IEC/NEMA motors ensuring fast and low cost replacement

- Oil tight gear head keeps motor replacement free from oil spills

- Cast iron case with epoxy-polyester powder-coated finish for strength and durability

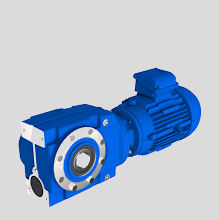

K Series

Bevel helical gear unit with torque capacities up to 33,000Nm, power up to 160kW and ratios up to 160:1 in three stage and up to 35,000:1 in combined form.

Can be supplied as triple and quintuple reduction units; foot, flange or shaft mounted. Available as motorised, motor ready or as a reducer with a keyed input shaft.

- Reduction gear and geared motor options

- Power up to 160kW covering the majority of drive requirements

- Ratios: up to 160:1 in three stage, up to 35,000:1 in combined form offers wide speed range

- Output torque up to 33,000Nm providing low cost per Nm

- Interchangeable Euro dimensions for ease of replacement

- Accepts standard IEC/NEMA motors ensuring fast and low cost replacement

- Oil tight gear head keeps motor replacement free from oil spills

- Cast iron case with epoxy-polyester powder-coated finish for strength and durability

S Series

Helical worm gear unit with torque capacities up to 10,000Nm, power up to 45kW and ratios up to 250:1 in two stage and up to 60,000:1 in combined form.

Can be supplied as double, triple, quadruple and quintuple reduction units; foot, flange or shaft mounted. Available as motorised, motor ready or as a reducer with a keyed input shaft.

- Reduction gear and geared motor options

- Power up to 45kW covering the majority of drive requirements

- Ratios: up to 250:1 in two stage, up to 60,000:1 in combined form offers wide speed range

- Output torque up to 10,000Nm providing low cost per Nm

- Interchangeable Euro dimensions for ease of replacement

- Accepts standard IEC/NEMA motors ensuring fast and low cost replacement

- Oil tight gear head keeps motor replacement free from oil spills

- Cast iron case with epoxy-polyester powder-coated finish for strength and durability

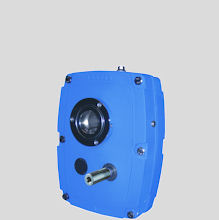

F Series

Shaft mounted gear unit with torque capacities up to 16,500Nm, power up to 110kW and ratios from 5:1 to 100:1 in double reduction and up to 5,600:1 in combined form.

Can be supplied as double, triple, quadruple and quintuple reduction units in flange or shaft mounted execution. Available as motorised, motor ready or as a reducer with a keyed input shaft.

- Reduction gear and geared motor options

- Power up to 110kW covering the majority of drive requirements

- Ratios: up to 5:1 to 100:1 in double reduction and up to 5,600:1 in combined form offers wide speed range

- Output torque up to 16,500Nm providing low cost per Nm

- Interchangeable Euro dimensions for ease of replacement

- Accepts standard IEC motors ensuring fast and low cost replacement

- Oil tight gear head keeps motor replacement free from oil spills

- Cast iron case with epoxy-polyester powder-coated finish for strength and durability

JPM Series

Worm gear unit available with torque capacities of up to 520Nm (4kW motor) and with a standard gear ratio range of 5:1 to 70:1. Available as foot, flange and shaft mounted types.

- Motorised and speed reducer types for all applications

- Variable mounting options allow design flexibility

- Unique Holroyd gear tooth profile for high efficiency and long life

- High torque capacities, yet compact design

- Wide ratio range gives speeds to match design demands

- Long life synthetic lubricant factory filled

- Optional case protection for use in hostile and arduous environments

- Hollow output shaft option for direct shaft mounting

- Plug-in and solid output shafts single and double extension

PM Series

The PM Series range is available in 6 sizes with power capacities up to 84kW and gear ratios from 5:1 to 333:1.

The geared motor units are available as:

- Single worm units - Type PW

- Helical / worm units - Type PH

- Helical / bevel units - Type PB

Features & Benefits

- Bevel helical version offers reduced running costs through high efficiency.

- Worm helical version provides wide range of ratios allowing for optimum speed selection.

- Accepts all standard IEC motors with trouble free plug in design allowing customer specific motors to be accomodated.

- Vertical output dry well eliminates process contamination and possible catastrophic failure due to loss of lubricant.

- Integrated hold back provides process security in inclined applications.

- UK designed and manufactured ensuring outstanding customer service.

- Peace of mind with proven design tested throughout industry

TW Series

Heavy duty worm gear unit for arduous applications having a size range of 10" to 28" nominal (250 - 710mm) centre distance. Available as single or double reduction units, with power capacity of up to 1500kW.

- Heavy duty design for high torque applications.

- Variety of unit types enables flexibility in design mounting

- Unique Holroyd tooth form provides high efficiency and product life.

- Optional protection for hostile and arduous environments.

- Interchangeable with David Brown Radicon

- Replacement for Flender Cavex

TW Series Worm Gear Product Features

- Phosphor bronze wormwheel rim electron beam welded onto cast iron centre on units up to size 14 to ensure maximum strength under shock load conditions.

- Unique Holroyd tooth profile for maximum torque capacity and optimum efficiency.

- Provision for synthetic lubricants for the transmission of higher torques where a more compact drive package is required.

- Two piece close grain cast iron gear case for strength and absorption of vibration for quiet running.

- Sprag clutch backstop option to prevent drive reversals.

- Heavy duty taper roller bearings fitted for maximum load capacity and long life.

- Enhanced sealing is available using a grease packed labyrinth system for use in hostile environments.

WM Series

The WM Series unit is available as a single or double reduction unit up to 4900:1 ratio, with a power capacity of up to 115kW.

The WM Series metric is available as a single reduction unit up to 70:1 ratio, with a power capacity of up to 98kW.

- High torque capacity - compact design

- Heavy duty version - for demanding applications

- Variable mounting - design flexibility

- Unique Holroyd tooth form - high efficiency and product life

- Motorised and speed reducer versions

- Adaptability - ideal for hostile environments

- Replacement for Flender Cavex

- Interchangeable - dimensionally interchangeable with the David Brown Radicon Series 'A' mid range

WM Series Product Features

- Unique Holroyd tooth profile for maximum torque capacity and optimum efficiency.

- Sprag clutch backstop option to prevent drive reversal.

- Double extension input shaft for use when two or more gear units are driven by one common prime mover.

- Heavy duty taper roller bearings fitted for maximum load capacity and long life.

- Two piece close grained cast iron gear case for strength and absorption of vibrations for quiet running.

- Phosphor bronze wormwheel rim electron beam welded directly onto the cast iron centre ensuring maximum strength under shock load conditions.

- Hollow and plug-in output shaft options for use as a direct coupled drive or shaft mounted directly onto the machine headshaft.

SMX Series

Shaft mounted speed reducers, SMSR, available as single reduction units with 5:1 ratios and double units with ratios of 13:1, 20:1, 25:1 metric and 15:1 North American.

- Rapid Response 'Off the Shelf' availability

- Interchangeable with Fenner (Eriks), Rexnord, Benzler, Sala and Dodge to allow fast and easy replacement.

- Robust construction ideal for heavy duty applications.

- Wide ratio range gives competitive size selections.

- Parallel and taper bore options allow easy removal for repair.

- Sprag clutch backstop available to prevent drive reversal.

- Enhance seal arrangements for use in hostile environments.

SMX Product Features

- Hardened and profile ground helical gears for maximum power transmission, smooth operation and long life, with maximum efficiency.

- High tolerance heavy duty roller bearings for trouble free operation and maximum load carrying capacity.

- Enhanced seal options on input and output for use in hostile environment conditions.

- Sprag clutch backstop option to prevent drive reversal.

- Heavy duty input shaft manufactured in high tensile alloy steel, suitable for all overhung load conditions.

- Close grain cast iron gear case giving robust case strength, quiet and vibration free running.

- Fully machined face on both sides of the gear unit for face mounting options.

- Parallel and taper bore output options available, allowing easy removal for replacement or repair.

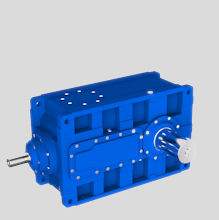

H Series

State of the art heavy duty helical and bevel/helical units using case hardened and ground gears throughout, 8 sizes with capabilities up to 162,000 Nm.

- Heavy duty design for high torque applications

- Variety of unit types enables flexibility in design mounting

- Wide ratio range gives speeds to match design demands

- Motorised and speed reducer versions

- Hollow and solid shaft variants allowing design options

- Custom made units designed specifically for customer's applications

H Series Product Features

- Fan and water cooling are available as design and selection options to allow greater torques to be transmitted at higher input speeds.

- Heavy duty taper and spherical roller bearings are used for maximum load capacity and long life.

- Gear cases are manufactured in close grain cast iron for absorption of vibration and quietness of running.

- All units are available with the option of output shaft, single or double extension, or hollow output for direct shaft mounting, suitable for all design options.

- Case hardened and profile ground helical gears with involute thread profile to give maximum power transmission, smooth operation and long life, with maximum efficiency.

- All units are Atex compliant and can be supplied against Group 2 or 3 for surface industries in designated Hazardous locations, Zones 1 and 2 for gases, vapours and mists and zones 21 and 22 for dust.

WH Series

The new WH Series Compact Transit Escalator Drive range comprises 5 footprint options to provide easy interchangeability with other manufacturers. The compact design drive is available as motor ready or fitted with a vertical motor, brake and flywheel package for in-truss installation.

Incorporating the unique Renold Holroyd Worm Gear Form on the high speed input stage and a helical gear on the second stage, the worm / helical combination is designed for high efficiency and low noise.

The unit also benefits from Renold's low oil level technology which reduces operating temperature and extends operating life. Optional use of non-contact labyrinth seals ensures that the new units are leak free.

Key benefits:

- Unique case design ensures interchangeability with other manufacturers without the need for re-engineering.

- Compact design available as motor ready or fitted with a vertical motor, brake and flywheel package for in-truss installation.

- Worm / helical combination unit designed for high efficiency and low noise.

- Uses Renold's low oil level technology to reduce operating temperatures and extend operating life.

- Optional use of non-contact labyrinth seals ensures that the units are leak free.